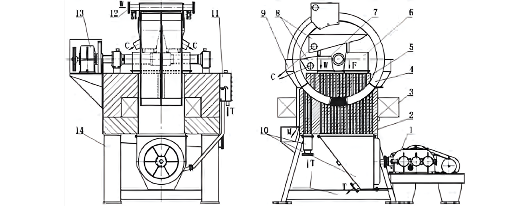

Vertical ring high-gradient magnetic separator

Vertical ring high-gradient magnetic separator is a high-tech beneficiation equipment. The separator is characterized by a high degree of beneficiation, increased operability at different material size and concentration, high reliability, and easy maintenance.

- The rotating ring is positioned vertically. Coarse grains do not exit through the magnetic medium, which prevents jamming.

- A pulsator is installed for hydro-mechanical force generation and pulp feeding. As a result, the purity of beneficiation is increased.

- The special magnetic system and optimal magnetic environment allow working with materials up to 2.0 mm in size, which simplifies the classification technology and ensures high workability.

- The special material tank allows the creation of a high-gradient magnetic field even in high-density disordered media.

- A robust lead box for easy on-site connection is provided.

- Special light and sound alarms and automatic shutdown in case of insufficient pressure or excessive cooling water temperature are provided to maximize coil life.

- Easy adjustment of technical parameters and magnetic field characteristics as well as rotating ring speed, pulse amplitude, and frequency is provided.

- Cooling of the control cabinet ensures safety.

| Type | CHDL-50 | CHDL-75 | CHDL-100 | CHDL-125 | CHDL-150 | CHDL-175 | CHDL-200 | CHDL-250 | CHDL-300 | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Modification | M | T(ТЗ) | M | T(ТЗ) | M | T(ТЗ) | M | T(ТЗ) | M | T(ТЗ) | M | T(ТЗ) | M | T(ТЗ) | M | T(ТЗ) | M | T(ТЗ) | |

| Outer diameter rotating ring, mm | 500 | 500 | 750 | 750 | 1000 | 1000 | 1250 | 1250 | 1500 | 1500 | 1750 | 1750 | 2000 | 2000 | 2500 | 2500 | 3000 | 3000 | |

| Rotation speed of the ring, rpm | 0.3-3 | 0.3-3 | 0.3-3 | 0.3-3 | 0.5-4 | 0.5-4 | 0.5-4 | 0.5-4 | 0.5-4 | 0.5-4 | 1-4 | 1-4 | 1-4 | 1-4 | 1-4 | 1-4 | 1-4 | 1-4 | |

| Feed size ore (-200 mesh%), mm | 1 | 1 | 1 | 1 | 1.2(30-100) | 1.2(30-100) | 1.2(30-100) | 1.2(30-100) | 1.2(30-100) | 1.2(30-100) | 1.2(30-100) | 1.2(30-100) | 1.2(30-100) | 1.2(30-100) | 1.2(30-100) | 1.2(30-100) | 1.2(30-100) | 1.2(30-100) | |

| Concentration fed ore, % | 10-40 | 10-40 | 10-40 | 10-40 | 10-40 | 10-40 | 10-40 | 10-40 | 10-40 | 10-40 | 10-40 | 10-40 | 10-40 | 10-40 | 10-40 | 10-40 | 10-40 | 10-40 | |

| Passing capacity pulp, m3/h | 0.25-0.5 | 0.25-0.5 | 0.5-1 | 0.5-1 | 12.5-20 | 12.5-20 | 20-50 | 20-50 | 50-100 | 50-100 | 75-150 | 75-150 | 100-200 | 100-200 | 200-400 | 200-400 | 350-650 | 350-650 | |

| Capacity dry, t/h | 0.03-0.125 | 0.03-0.125 | 0.06-0.25 | 0.06-0.25 | 4-7 | 4-7 | 10-18 | 10-18 | 20-30 | 20-30 | 30-50 | 30-50 | 50-80 | 50-80 | 100-150 | 100-150 | 150-250 | 150-250 | |

| Nominal magnetic field strength, T | 0.8 | 1(1.3) | 0.8 | 1(1.3) | 0.8 | 1(1.3) | 0.8 | 1(1.3) | 0.8 | 1(1.3) | 0.8 | 1(1.3) | 0.8 | 1(1.3) | 0.8 | 1(1.3) | 0.8 | 1(1.3) | |

| Rated current excitation, A | 1200 | 1200 | 1100 | 1200 | 650 | 1200 | 850 | 1400 | 950 | 1400 | 1200 | 1400 | 1200 | 1400 | 1400 | 1400 | 1400 | 1400 | |

| Excitation voltage, V | 8.3 | 13.4(20.3) | 12 | 20.3(25) | 26.5 | 26.5(37.8) | 23 | 28.5(40) | 28 | 34.7(44.3) | 31 | 38.2(51.5) | 35 | 39.2(56.2) | 45 | 56(78) | 62 | 80(93) | |

| Rated power at excitation current, kW | 10 | 16(24.4) | 13 | 24.4(30) | 17 | 31.8(45.4) | 19 | 40(56) | 27 | 46.8(62) | 37 | 53.5(72) | 40 | 55(78.7) | 63 | 78.4(109.2) | 87 | 112(130.2) | |

| Motor power of rotating ring, kW | 0.37 | 1.1 | 0.55 | 1.1 | 1.1 | 1.5 | 1.5 | 3 | 3 | 4 | 4 | 7.5 | 5.5 | 11 | 11 | 15 | 18.5 | 18.5 | |

| Power of pulse motor, kW | 0.37 | 0.37 | 0.75 | 0.75 | 2.2 | 2.2 | 2.2 | 2.2 | 4 | 4 | 4 | 4 | 7.5 | 7.5 | 11 | 11 | 18.5 | 18.5 | |

| Pulse stroke, mm | 0-40 | 0-40 | 0-40 | 0-40 | 0-30 | 0-30 | 0-20 | 0-20 | 0-30 | 0-30 | 0-30 | 0-30 | 0-30 | 0-30 | 0-30 | 0-30 | 0-30 | 0-30 | |

| Pulse frequency, times/min | 0-400 | 0-400 | 0-400 | 0-400 | 0-300 | 0-300 | 0-300 | 0-300 | 0-300 | 0-300 | 0-300 | 0-300 | 0-300 | 0-300 | 0-300 | 0-300 | 0-300 | 0-300 | |

| Pressue of supplied water, MPa | 0.1-0.2 | 0.1-0.2 | 0.1-0.2 | 0.1-0.2 | 0.2-0.3 | 0.2-0.3 | 0.15-0.3 | 0.15-0.3 | 0.2-0.3 | 0.2-0.3 | 0.2-0.3 | 0.2-0.3 | 0.2-0.3 | 0.2-0.3 | 0.2-0.4 | 0.2-0.4 | 0.2-0.4 | 0.2-0.4 | |

| Water flow rate, m3/h | 0.75-1.5 | 0.75-1.5 | 1.5-2.5 | 1.5-2.5 | 10-20 | 10-20 | 30-45 | 30-45 | 60-90 | 60-90 | 80-120 | 80-120 | 100-150 | 100-150 | 200-300 | 200-300 | 350-530 | 350-530 | |

| Volume of cold water, m3/h | 1.5-2 | 1.5-2 | 1.5-2 | 1.5-2 | 2-2.5 | 2-2.5 | 2.5-3 | 2.5-3 | 3-4 | 3-4 | 4-5 | 4-5 | 5-6 | 5-6 | 6-7 | 6-7 | 8-10 | 8-10 | |

| Weight of the main machine, t | 17 | 2.1 | 3 | 3.6 | 6 | 6.8 | 14 | 16 | 20 | 25.5(26.8) | 35 | 41.3(42.6) | 50 | 55(57) | 105 | 113(118) | 175 | 188(196) | |

| Weight of maximum unit, t | 0.3 | 0.5 | 0.6 | 0.9 | 2.22 | 2.5 | 4 | 6 | 5 | 5.8(7.6) | 11 | 9(11.5) | 14 | 20(21.5) | 15 | 19.5(22) | 16 | 21(22) | |

| Overall dimensions (LxWxH), mm | 1800×1400×1320 | 1400×2000×1600 | 2000×1360×1680 | 1500×2000×2100 | 2700×2000×2400 | 2100×2600×2800 | 3200×2340×2700 | 2600×2950×3150 | 3600×2900×3200 | 2950×3550×3600 | 3900×3300×3800 | 3600×3370×4100 | 4200×3550×4200 | 4200×3700×4630 | 5800×5000×5400 | 5650×5150×5900 | 6600×5300×6400 | 6450×5500×6550 | |