Dry drum magnetic separator

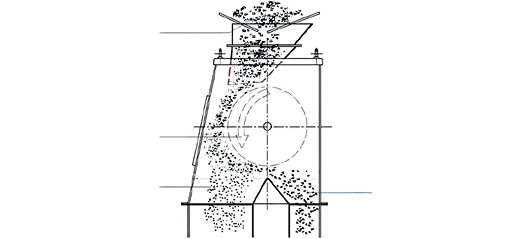

The permanent magnet dry drum magnetic separator is used for automatic continuous removal of iron from dry fine material. The inner coating is made of rare earth material with permanent magnetic properties to maintain the magnetic field. The magnetic field spreads radially around the drum body with a certain angle (120°–200°, standard design is 175°) according to the operational requirement.

Outside the rotating drum made of stainless steel, a gradient magnetic field is generated, which helps to remove iron, iron filings, iron oxide and other magnetic substances. When materials come in contact with the rotating drum, the magnetic substances in the material are attracted to the surface of the drum by the high magnetic force and transferred to the non-magnetic area of the rotating drum.

At the same time, the magnetic substances are forced into the iron tank by gravity and centrifugal force. The non-magnetic substances do not rotate and are transferred to the discharge hopper. In this way, the magnetic substances in the material are separated from the non-magnetic substances, and automatic iron removal or cleaning is realized.

- Strong magnetic source, low energy consumption, stable magnetic force.

- High intensity magnetic field on the drum surface, large gradient and large attraction force.

- Multipole magnetic field structure improves the efficiency of magnetic rotation and separation.

- The drum shell is made of high quality non-magnetic stainless steel and wear-resistant steel.

- Automatic iron unloading.

- Box design with flange connection. Can be connected to closed production line.